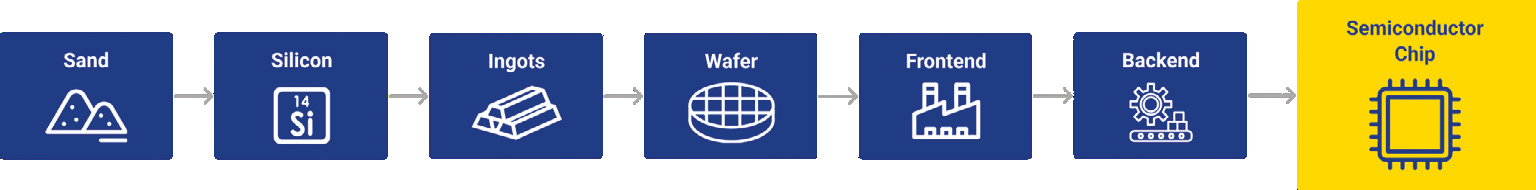

Semiconductor manufacturing is the most complex manufacturing process that exists today and requires hundreds of production steps to change the raw semiconducting material into useful devices. At the most basic level, silicon is converted from sand to an ultra-high purity level. The refined material is melted into cylindrical crystals (called ingots) and sliced into half-a-millimetre thick wafers with diameters of 150, 200 or 300 mm.

These wafers are then repeatedly coated with thin layers of functional materials, patterned, and etched to create the transistor structures on them. Several hundreds of highly developed process steps are carried out and repeated. To complete the processing and to create final products, a range of additional materials, including chemicals, metals, plastics, specialty gases, and many more are needed. All these steps are essential and require highest manufacturing precision. Therefore, hundreds of tests and measurements are performed to ensure the functionality of the chip in this so-called ‘frontend’ manufacturing.

Next, the wafers are cut into individual chips, which are again assembled, packaged into multi-layered chip devices in plastic or ceramic to form a final product to protect the technology inside, and finally tested (‘backend’ manufacturing). The steps are increasingly intricate as technology advances.

💡 Purity levels of 99.9999999% or higher are required for silicon wafers and other inputs, meaning that less than 1 foreign atom per 1 billion is tolerable.

💡 A chip is likely to cross international borders some 80 times and travel 2.5 times around the globe before being finalised.