Electricity, Water and Waste

Energy – “Doing more with less”

The semiconductor industry has a small proportionate share of energy consumption in its production processes when compared with other global manufacturing industries. The industry is nevertheless very focused on continually innovating in order to achieve energy reductions at its production factories (fabs). Through ESIA as well as through partnerships with its equipment suppliers and international research consortia, the European industry develops, shares and implements best energy performance practices in its manufacturing facilities. This is an area where win-wins are created by sharing relevant pre-competitive information on reducing energy consumption at the fab level. Setting targets for an industry is a crucial part of reducing the amount of electricity, water and the waste produced attributable to the manufacturing process.

Managing Water Usage

ESIA semiconductor companies also are very focused on managing their water footprint and the amount of water they use in the manufacture of semiconductor devices.

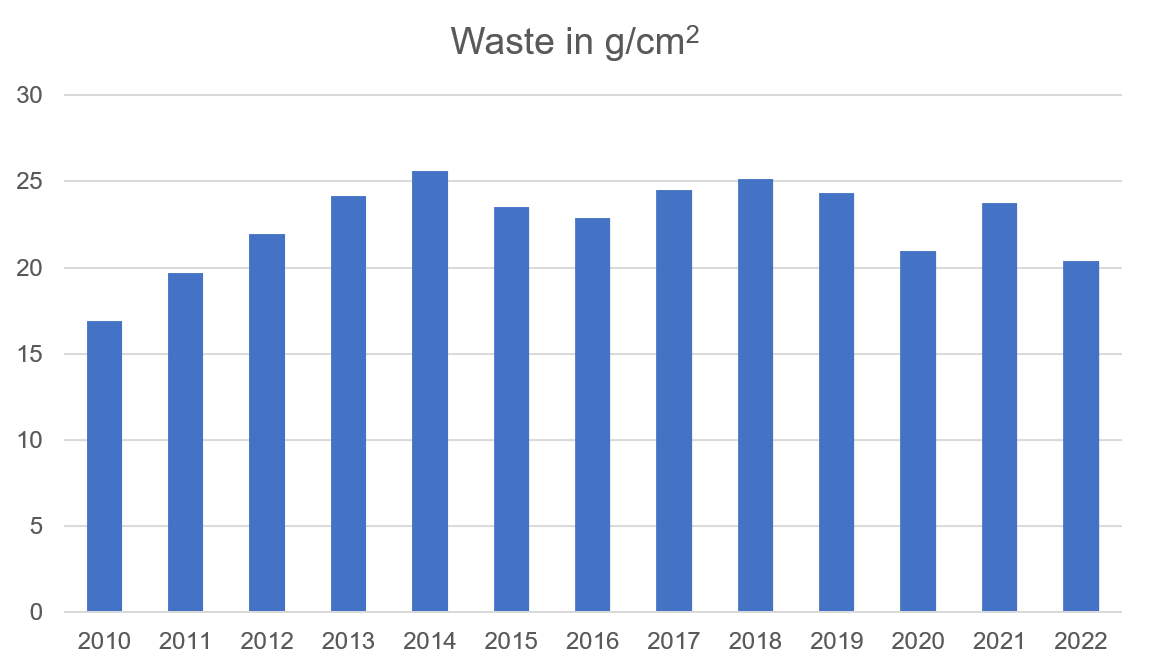

Reducing Waste

The semiconductor industry is committed to continuously reducing, reusing, and recycling and managing waste streams from manufacturing sites. The industry also has waste targets which are set to reduce the total waste produced per production unit.

February 2025: ESIA Position Paper on the Water Resilience Strategy